"Physicians are encouraged to identify and address care gaps as part of their bi-annual initiatives. Providing timely access to care, and identifying patients who need to be seen preemptively, can lead to improved care at a lower cost."

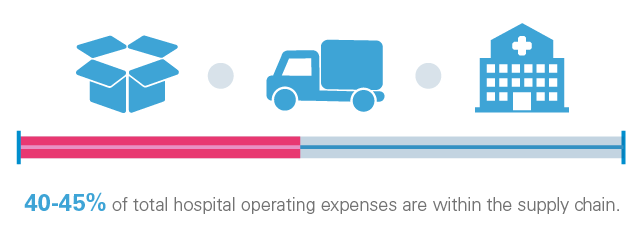

Supply Chain Optimization

An Interview With

Working with You for a Better Supply Chain

As part of the Massachusetts Institute of Technology's Leaders for Global Operations (LGO) program and Boston Scientific’s Supply Chain Optimization Services, M.B.A. recipient Suman Machinani, M.D. led a supply chain process-improvement pilot program at a hospital endoscopy department — revealing opportunities that can be reproduced at other Boston Scientific customers' facilities.

With patient lives at stake every day, healthcare as an industry must exercise caution when implementing new ideas that other industries would readily adopt with a spirit of innovation. This restraint, though, can be turned into an advantage as healthcare – following in the footsteps of other industries – can observe best practices while avoiding pitfalls that early adopters experience.

Synchronizing materials management for better patient care

Healthcare has to coordinate increasingly complex supply networks to bring the best possible care to the bedside, office or home. It needs to cover most people, at the fairest cost. Static planning and scheduling, no matter how precise, will never be robust.

Decreases in Annual Supply Chain Costs

Why is this significant?

How a device manufacturer became part of the cost savings solution

In a three-year period, Geisinger Health Systems realized a savings of approximately one million dollars by finding ways to better manage its inventory.

GS1/GTIN Transition: Global Standards Helping Customers Improve Supply Chain Efficiencies

GS1 are the most widely used supply chain standards in the world. By adopting these standards and implementing Global Trade Item Numbers (GTIN) for its packaging, Boston Scientific is helping to better serve its customers and play a part in improving supply chain efficiencies.

GTINs adhere to GS1 standards and serve as globally unique identification numbers of an item in the supply chain as it moves from manufacturing through distribution and use. The GTIN numeric code and corresponding bar code identify key product attributes.